Maintenace and instructions of hydraulic ram

Maintenace and instructions of hydraulic ram

How to repair hydraulic ram

(1) First of all, open the box to check if all parts are available, then, fetch the hydraulic ram, please use your left hand to take ram and use your fingers of right hand to turn slowly in order to check if the ram ring is stretched out. If ram ring is stretched out about 1/2 inch (15mm), means ram ring is normal and useful. But if the length which ram ring stretch out is not enough or ram ring not-stretch out, means the oil-seal of ram is not enough, then we shall maintenance it according to the following steps.

(2) Steps of maintenance when oil for oil-seal of ram is not enough:

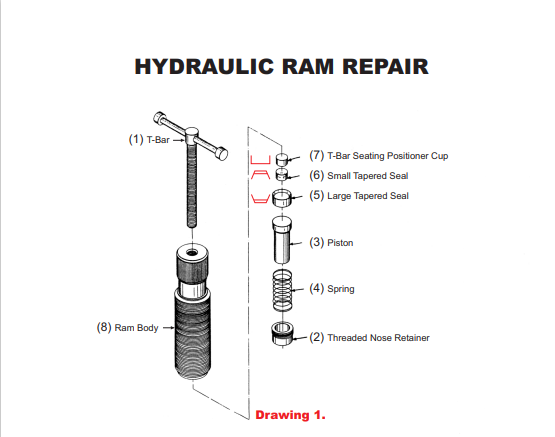

a. First, turn the T-handle (1) left to fetch out, make terminal of ram contact with atmospheric pressure outside, from balance between the pressure inside and outside the ram. Please refer to drawing 1.

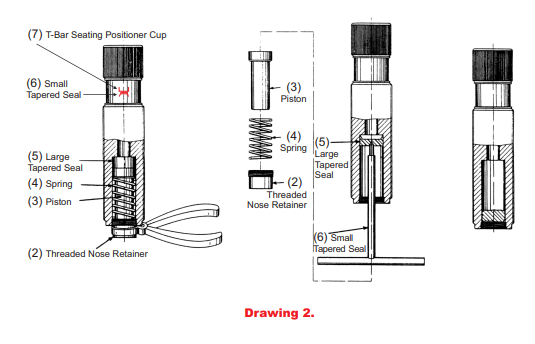

b. Then, use circular clip to clip circular part of ram cover (2) which is on the side of cover, turn cover (2) in order to make screw backward, then fetch out ram cover (2) and take ram ring (3) and spring (4) in order. Please refer to drawing 2.

c. Then, fetch out plastic seal (5), now you must take care that you have to take plastic seal (5) according to the following method slowly: The method is to extend T-type screw handle (6) form side of ram, order to make T-type screw handle (6) parallel with ram and turn into plastic seal (5) straightly about 2mm depth (the depth can't be too long in order to prevent from damage of plastic seal (5)), then pull out T-type screw handle (6) parallel with ram, fetch out plastic seal (5) from ram slowly, now you must prevent damage of plastic seal (5). Then, spread greasy lubricating oil (bearing oil) around ram. You just have to spread 0,020kg bearing oil only.

d. After you have spreader bearing oil around ram, you must check if the directions of plastic seal (5) and plastic seal (7) are right before assembly, that is, grooves of plastic seal (5) and plastic seal (7) are opposite. Please refer to drawing 1, check if groove of plastic seal (5) toward inside before assembly, that make plastic seal (5) with better oil-seal function.

Sometimes lack of oil leak out occur, it is not during to damage of hydraulic gear puller, it's because changeable weather, for example, bearing oil will when temperature is very high. So if you find bearing oil is not enough, you just only have to add some bearing oil, then you can go on using. Please don't have to worry about it. If bearing oil enough, hydraulic gear puller can work forever.

Are you looking for a reliable manufacturer of Automotive Tools&Hand Tools?

We can quickly provide customers with market analysis, technical support and customized services.subscription