What additional features do nut splitters have?

Most of the additional features available on some nut splitters allow you to fit them on nuts in awkward and confined spaces.

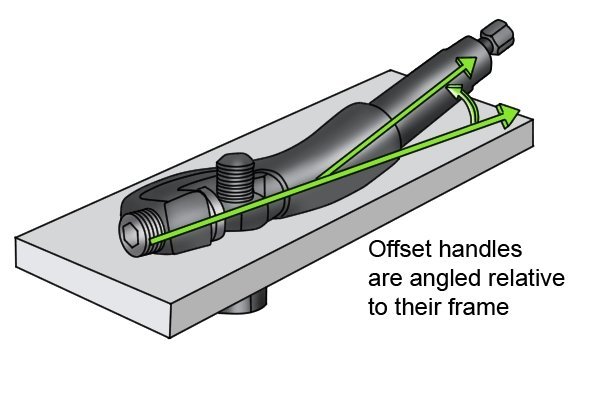

Offset handle

Some nut splitters have an offset handle which is angled in relation to the frame. This allows the nut splitter to be used in more situations, such as when a nut is on a flat surface which can make turning the screw head of other nut splitters awkward.

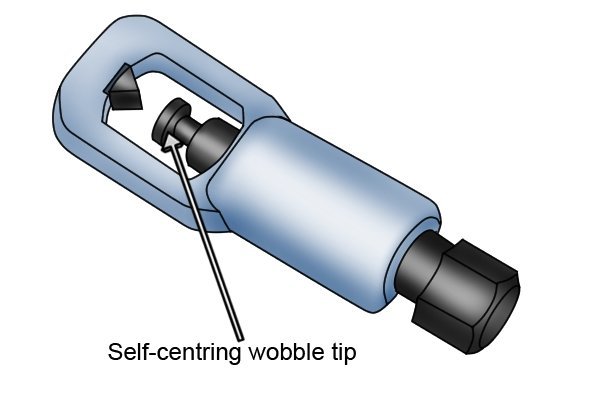

Self-centering wobble tip

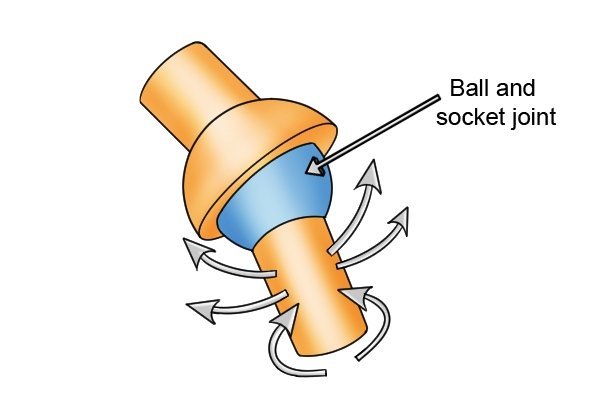

This feature allows the anvil of the nut splitter to articulate using a ball and socket joint. By doing this the handle of nut splitter doesn’t need to line up perfectly with the flat of the nut. Instead the self-centering wobble tip will allow the nut to be pinched between its flats with the anvil and chisel kept at right angles to the flats while the handle is slightly angled.

In order to keep the chisel and anvil at right angles to the nut’s flats when the handle is not, the chisel cannot be driven by the screw. So instead the chisel and anvil swap sides and the anvil is connected to the screw with the self-centering wobble tip.

This can enable nut splitters to be used on nuts in more confined situations where obstructions might prevent you from lining up the chisel of other nut splitters square against the flat of the nut.

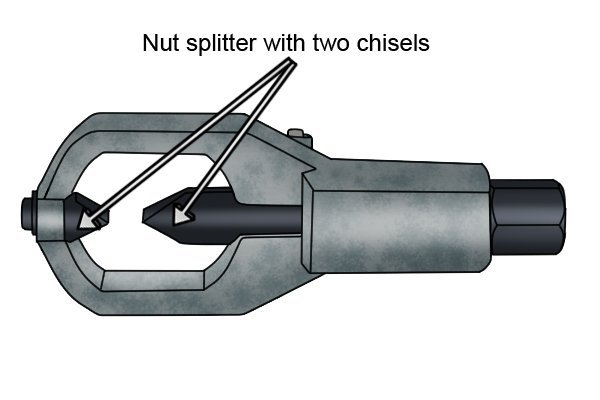

Double chisel

As the name suggests a double chisel nut splitter has two chisels. Only one of the chisels moves when the screw is turned, but this pinches the nut between the two chisels. The two chisels cut into the nut’s flats from opposite sides of the nut.

This can speed up the time taken to cut the nut from the bolt or stud. Also the second chisel can cut into the other side of the nut without having to remove and reposition the nut splitter, where its handle may prevent you from positioning it on the nut.

Screw-adjustable anvil

Screw-adjustable anvils are found on C-frame nut splitters with a hydraulic screw action. As the chisel of these nut splitters does not move a great distance due to the hydraulic ram (see How does a nut splitter work?) the screw adjustable anvil allows the nut splitter to still be used on a wide range of nut sizes, by moving in and out of the C-frame to sandwich the nut up against the chisel.

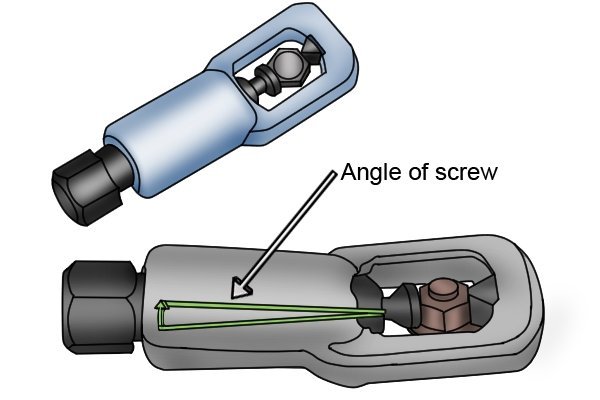

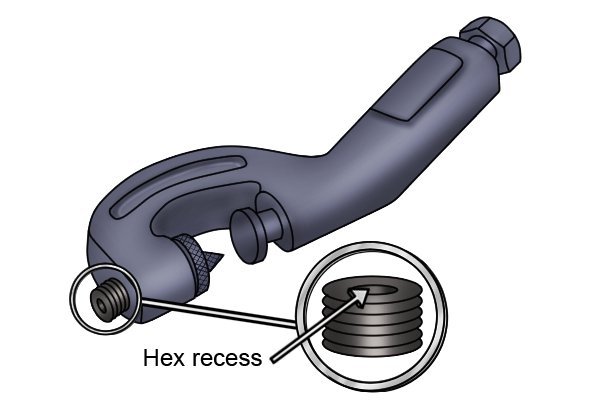

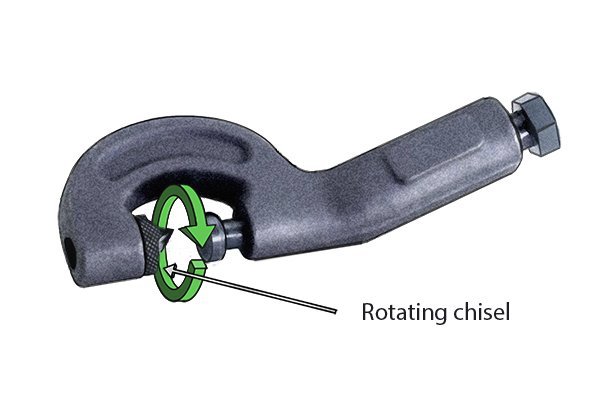

Rotating chisel

Rotating chisels are usually seen on C-frame nut splitters. Like the screw-adjustable anvil they are adjusted with a hex key that fits into the hex recess at the end of the threaded shaft connected to the chisel. Because of this they are not connected to the screw and instead switch places with the anvil of the nut splitter.

The rotating chisel allows you to use the nut splitter with the C-frame rotated at any angle over the head of the nut, while keeping the chisel square against the flat of the nut. This feature allows these nut splitters to be used in more awkward and confined spaces, such as on the underside of vehicles.

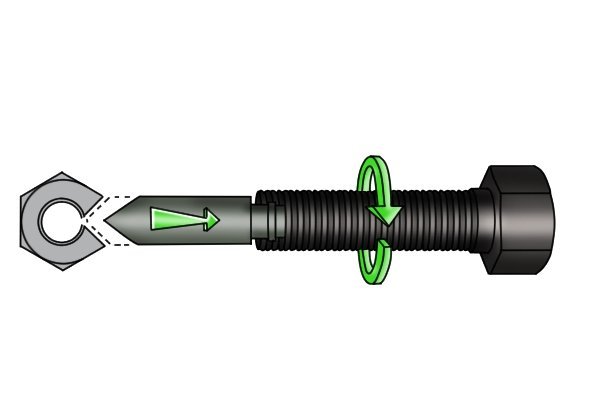

Attached chisel and screw

As the chisel is pressed into the flat of the nut it can sometimes become wedged in. If this happens, the nut remains firmly attached to the chisel as the screw is wound back. Some manufacturers have designed nut splitters with a chisel that is attached to the screw, so as the screw is wound back it pulls the chisel back away from the nut.

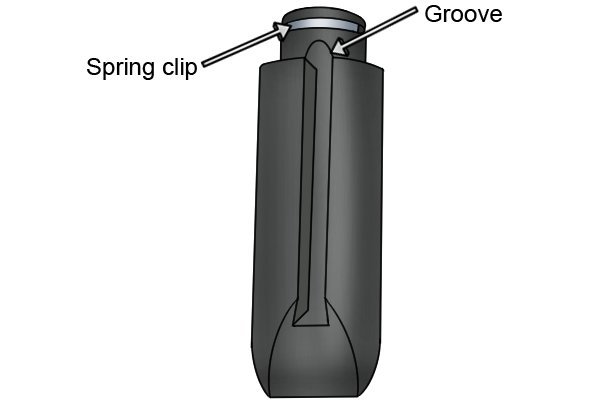

The chisel is held in the recess at the end of the screw by a spring clip. A groove runs along the chisel, into which the grub screw fits, preventing the chisel from rotating.

Are you looking for a reliable manufacturer of Automotive Tools&Hand Tools?

We can quickly provide customers with market analysis, technical support and customized services.subscription