How to clean Cylinder Honing And Block Engine Rebuild Part 4

If new piston rings are installed, the cylinder walls MUST be given an appropriate scratch pattern. The scratches help the new rings "wear in", and they also hold oil on the cylinder wall, which reduces the wear on the piston rings and the cylinder. It might even improve fuel economy because the engine has less internal friction.

The best way to get the proper scratch pattern is with an electric drill and a ball hone, which will demonstrate below.

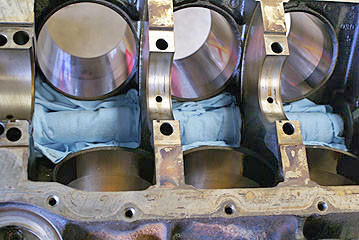

To keep grit and debris away from the camshaft during cylinder honing, I placed paper towels over the 3 exposed sections of camshaft.

I tucked the paper behind the cylinder wall portion of the engine block casting. (I'm not planning on replacing the camshaft.)

Notice how shiny the cylinders are... this happens after 160,000 miles of use. Shiny is NOT good.

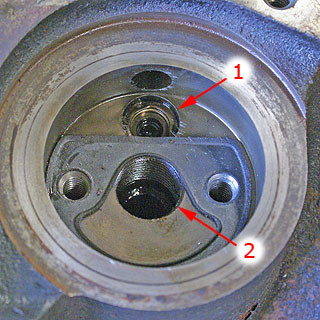

Note the oil filter area at the rear of the engine (driver's side). On larger trucks, the oil filter goes here, but on the Blazer/Jimmer, they install an adapter here and run oil lines up to the front of the vehicle.

I forgot to cover up this area when I first turned the engine upside down, and I became concerned that some dirt may have gotten into the oil passageways. I later realized that this isn't a serious risk because there is a check valve on the "clean" side of the oil system (arrow 1). The check valve holds the oil in the galleries when the engine is shut off, preventing all the oil from draining back into the pan. The big hole (arrow 2) carries dirty oil to the filter.

When the engine was back in the car, I sprayed some brake cleaner on the check valve to remove any grit or debris. Still, it's a good idea to keep this covered.

A simple way to prevent problems is to stuff a paper towel or clean rag in the oil filter adapter bore.

This is a 4-1/8" Flex-Hone, or ball hone.When used with an electric drill, this tool is used to create a diamond-shaped scratch pattern on the cylinder walls. The proper scratch pattern is necessary when new piston rings are installed, so the rings "seat" themselves properly. The scratch pattern helps the cylinder wall retain oil so the rings are always lubricated properly.

I applied some 10W-30 motor oil to the Flex-Hone WHILE SPINNING. The hone must be lubricated before using it in each cylinder.

To apply the oil, I rigged up a squirt bottle from an empty bottle of Lucas Oil Stabilizer. First I cleaned out the Lucas residue with paint thinner, then I blew out the liquid with compressed air. Next I sprayed some carburator cleaner into the bottle, swished it around, and poured it out. I blew the bottle out again and it was clean. I cut a tiny hole in the squirt tip of the Lucas bottle and poured in a quart of 10W-30 motor oil.

While the Flex-Hone can be chucked into any 3/8" electric drill, many smaller drills spin at 1200 RPM or more, which is too fast for this procedure.

started the drill and plunged the Flex-Hone into the cylinder.

ran the brush up and down about once per second while spinning at full speed (850 RPM for this drill). Stroking up and down once per second means moving your arms really fast.

Caution: This procedure sprays oil around the work area and can make quite a mess.

Running this tool properly, and getting the proper angle, is kinda tricky. You are only supposed to run the flex hone for about a minute per cylinder, so you can't exactly practice very much on a good engine.

the angle of the scratch pattern by the angle of the swirls in the oil on the cylinder wall.

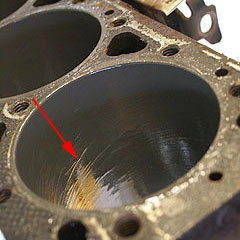

After wiped off the oil with a paper towel and carb cleaner, I noticed that cylinder 6 still had some black raised spots.

These spots formed a ring around the cylinder, which makes me believe they are rust spots from the engine sitting so long.

You may recall that the top ring on number 6 piston was rusted and stuck in the groove.

bought a rigid hone.then placed this in the drill motor and ran the hone up and down in the cylinder for about a minute. next applied oil to the stones and the cylinder wall before honing. This hone removed some, but not all, of the raised black spots.

Cleaning The Engine Block Deck:

The mating surfaces between the engine block and cylinder heads must be clean and free of residue from the old gaskets.Then there is the issue of surface smoothness. If you ever read a book on engine rebuilding, you will discover that the smoothness of the mating surfaces between the engine block and cylinder heads can be a HUGE issue. This is especially true with aluminum cylinder heads, which expand more than cast iron and need to slide laterally as they heat up.

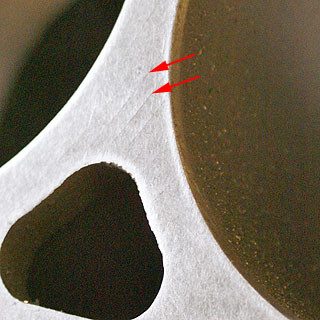

This is a 3M Roloc Bristle Disc,The yellow disc has 80 grit abrasive embedded in the plastic. There is also a green disc (50 grit) and a white disc (120 grit). These devices are used with a Roloc adapter (which also holds the conventional Scotch-Brite abrasive discs) in a die grinder that accepts a 1/4" shaft. This tool could also be used in a drill, but the RPMs are probably too slow for most people.

used the Roloc Bristle Disc to clean the rubbery gunk from the "deck" of the engine block.

used a random orbital sander with 220 grit sandpaper to remove the scratches from the engine block deck.

Note the pattern of tiny grooves from the original deck machining process.

Finally, sanded the deck with an orbital sander with 320 grit sandpaper.

used this orbital sander because I could not find Velcro-backed sandpaper discs finer than 220 grit. Adhesive-backed sanding discs are available up to 320 or 400 grit, and are used in the auto body trade with pneumatic sanders.

Cleaning The Head Bolt Holes:

ran a 3/8 inch brass bottle brush through each bolt hole (red arrow).

snipped off the loop handle on the end of the brush and chucked it in my cordless drill.

At this point it would be a good idea to "chase" all the head bolt holes with a tap. These holes have a 7/16" - 14 thread.did this procedure later, just before installing the cylinder heads.

Washing The Engine Block:

Honing the cylinders liberates A LOT of very abrasive grit from the ball hone and deposits that debris on the cylinder walls and possibly the lower crankcase.

Removing this debris completely is VERY IMPORTANT, or the rebuilt engine may develop scoring on the cylinder walls or some other type of dirt-related failure.

While it's tempting to use solvents (e.g. mineral spirits, carb cleaner, brake cleaner) to remove the grit-impregnated oil from the cylinders, the best method is to use regular laundry detergent and hot water. Just mix it extra strong.

To keep water out of the lifter valley, taped a sheet of plastic over the valley.I also installed the old timing chain cover to keep water away from the timing gear area.

Cleaning Debris From The Block:

mixed two cups of laundry detergent with two gallons of very hot water and poured some liquid into a small garden sprayer.

sprayed the detergent into the cylinders and scrubbed them with a dishwashing brush.

Don't expect to see much suds. Laundry detergent doesn't make a lot of suds.

sprayed some detergent into the cooling passageways and scrubbed them with an old toothbrush.

sprayed more detergent into the cooling passageways and then rinsed the cylinders and deck with a garden hose. I sprayed water into each hole in the deck and quite a bit of dirty water came out of the other holes. I tipped the engine block over so the deck was facing down and ran water into the water pump opening (on the front of the block) for a minute.

Then I blew off as much water as possible with compressed air and a blow gun. I wiped off any visible water with paper towels. At this point I began noticing rusty streaks forming, so I applied some motor oil to a paper towel and wiped the cylinders with oil, as well as the deck. I needed to keep the bare iron deck surfaces oiled while the engine block dried. Before installing the cylinder heads, I can remove the oil with brake parts cleaner.

I set up a large fan to blow air on the engine block to dry up any remaining water.